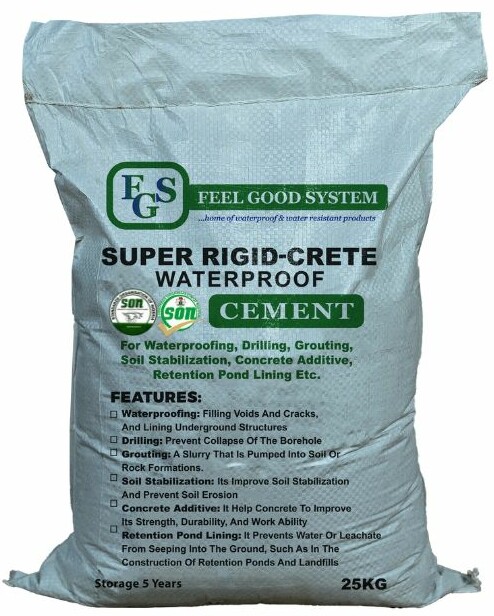

Super Rigid Crete 25kg

FREE

Description:

Description:

Super Rigid Crete has a number of applications in the construction industry. Here are some of the most common uses of Super Rigid Crete in construction:

- Waterproofing: Super Rigid Crete is an excellent material for waterproofing applications, such as filling voids and cracks, and lining underground structures. When mixed with water, super Rigid Crete forms a gel-like substance that can effectively prevent water from seeping through.

- Drilling: Super Rigid Crete is a popular drilling viscosity (slurry/mud). The Super Rigid Crete slurry (viscosity) helps to cool the drill bit, suspend the cuttings, and prevent collapse of the borehole. Super Rigid Crete slurries are also used to support excavation works during drilling operations.

- Grouting: Super Rigid Crete is commonly used in grouting applications, where it is mixed with water to form a slurry that is pumped into soil or rock formations. The slurry fills gaps and voids, effectively stabilizing the ground and preventing seepage.

- Soil Stabilization: "A process that reduces permeability and plasticity, while increasing compressive strength and load-bearing properties".. Soil do not fail in compression rather by shear. Soil only need shear strength parameters. That is cohesion and angle of internal friction. Maybe this product can increase cohesion. Super Rigid Crete can be used to stabilize soil in construction applications, such as road construction and foundation works. The super Rigid Crete slurry is mixed with the soil to improve its stability and prevent soil erosion. Super Rigid should be used at lower ratios (500gm-2kg per square meter 1-5%)

- Concrete Additive: Super Rigid Crete can be used as an additive in concrete to improve its strength, durability, and workability. Super Rigid Crete is added to concrete mixtures to reduce shrinkage, improve adhesion, Swimming pool and increase the resistance to chemical attack.

- Retention Pond Lining: Super Rigid Crete makes effective pond liners, where it prevents water or leachate from seeping into the ground, such as in the construction of retention ponds and landfills.

- Swelling Capacity: Super Rigid Crete has a high swelling capacity (5-15 times its dry volume) due to the properties it contained, which allows it to absorb and retain water or other liquids.

- Plasticity: Super Rigid Crete is highly plastic and can be molded into a variety of shapes without cracking or breaking.

- Adsorption Capacity: Super Rigid Crete also has a high adsorption capacity, which means it can attract and hold onto other molecules or particles. This makes it useful in a variety of applications, including water treatment, where it can be used to remove impurities from water.

- Viscosity: Super Rigid Crete is highly viscous (ave. η 23,400 mPa·s ± 120.4 mPa·s). It can form a thick, sticky gel when mixed with water.

- Thermal Stability: Super Rigid Crete is thermally stable and can withstand high temperatures without losing its properties. This makes Super Rigid Crete a suitable material in the production of refractories.

- Ion Exchange Capacity: Super Rigid Crete has a high ion exchange capacity, which means it can easily exchange cations with other ions in a solution. Such property allows Super Rigid Crete to be used in the production of catalysts and as a soil amendment.

- Low Permeability: Super Rigid Crete is highly impermeable and can act as an excellent barrier to the movement of water and other liquids.

Guaranteed safe checkout: PAYPAL | VISA | MASTERCARD

Click 'Add To Cart' button to order yours now!

(You will receive your order within _2-7__ days)

:

{{ attribute.attributeName }}: {{ attribute.label }},

Price:

Super Rigid Crete is a safe material to handle, but it is important to take proper precautions when working with this material to ensure the safety of workers and the environment. Here are some tips for safely handling Super Rigid Crete in construction:

- Wear Protective Equipment: When working with Super Rigid Crete, it is important to wear protective equipment such as gloves, eye protection, and a dust mask to prevent inhalation of dust particles. The dust particles can cause respiratory problems, so it is important to minimize exposure.

- Use Proper Ventilation: If you’re working with Super Rigid Crete in an enclosed space, ensure proper ventilation to prevent the accumulation of dust particles. Use fans or other ventilation equipment to create an airflow that carries the dust particles out of the work area.

- Store Properly: Store Super Rigid Crete especially Super Rigid Crete waterproofing products in a dry and cool place to prevent moisture from entering and changing the properties of the material. Moisture can reduce the effectiveness of the material and make it harder to handle.

- Mix Correctly: Follow all instructions for mixing Super Rigid Crete. Do not mix the material with hot water or use high-speed mixing equipment as it can damage the properties of the Super Rigid Crete.

- Dispose Properly: Dispose of Super Rigid Crete waste properly to prevent contamination of the environment. Avoid dumping the material in waterways, storm drains, or other sensitive areas. Instead, dispose of the waste in a designated landfill or dispose of it as per the local regulations.

ADVANTAGES OF SUPER RIGID CRETE

- Achieve CBR levels of up to 180%

- Stabilizes all types of soil and limestone mixtures

- Achieve compaction easily up to 95%

- Dust control can be achieved to the highest rate

- Reduces road maintenance cost

- Increase contractor's profit

- Save cost and construction time